All fans and blowers are manufactured in our 110, 000 square foot, state-of-the-art.Less down time before replacement bearings are needed. Belt driven models utilize wider spacing between the fan bearings which increases.Less expensive, more compact and lighter weight. All of our Industrial Blowers are available with multiple wheel sizes and some areĪlso available with multiple housing widths from 50% to 100%, in 5% increments.ĭirect driven fans can be selected instead of larger, heavier, more expensive beltĭriven fans.We manufacture most models with both types of construction All aluminum or all stainless steel fan construction is “ not.Dependable service with few field problems. Operation minimizing equipment down time. Heavy duty, industrial components and continuous duty motors ensures long lasting.Superior strength over stitch welding or lock seams. All fabricated steel models have continuously welded housings for additional strength.Ideal for applications requiring spark resistant construction with quick deliveries. Spark resistant, cast aluminum wheels are standard in.

Most all types and models, with most accessories, are.The benefits of Cincinnati Fan Industrial Blowers are: In the ¼ to 125 horsepower range, with airflow capacities from 50 to 51,900 CFMĪnd static pressures from 1/8” to 78” SPWG. But,we do manufacture 14 models of Industrial Blowers that are designed and constructedĪs industrial type.

Performance, design and features that best meet those conditions.Ĭincinnati Fan does not manufacture any consumer or residential type blowers. The blower selection will be based on the type of blower that is best suited by After the first seven conditions are known, If the industrial blower will be used to create suction, pressurization, cooling,Ĭombustion air, forced ventilation or general ventilation, then only the first sevenĬonditions above need to be considered. Models HDBI (Heavy Duty Backward Inclined Blowers)Īnd HDAF (Heavy Duty Airfoil Blowers) are also used in many dustĬollector applications where the blower is on the clean side of the dust collector. The best models to use,įor conveying material through the fan, are Models PB, SPB or PBS Pressure Blowers and Model RBE Radial Blade Exhauster. Trim or fibers, only an open radial wheel should be used. If the material you will be conveying is log and stringy, like paper Theīest centrifugal wheel type for conveying material is a radial wheel or an open Material, a blower with a forward curve (squirrel cage) wheel is not suitable.

Most Industrial Blowers can be used for any of the above parameters except, if conveying

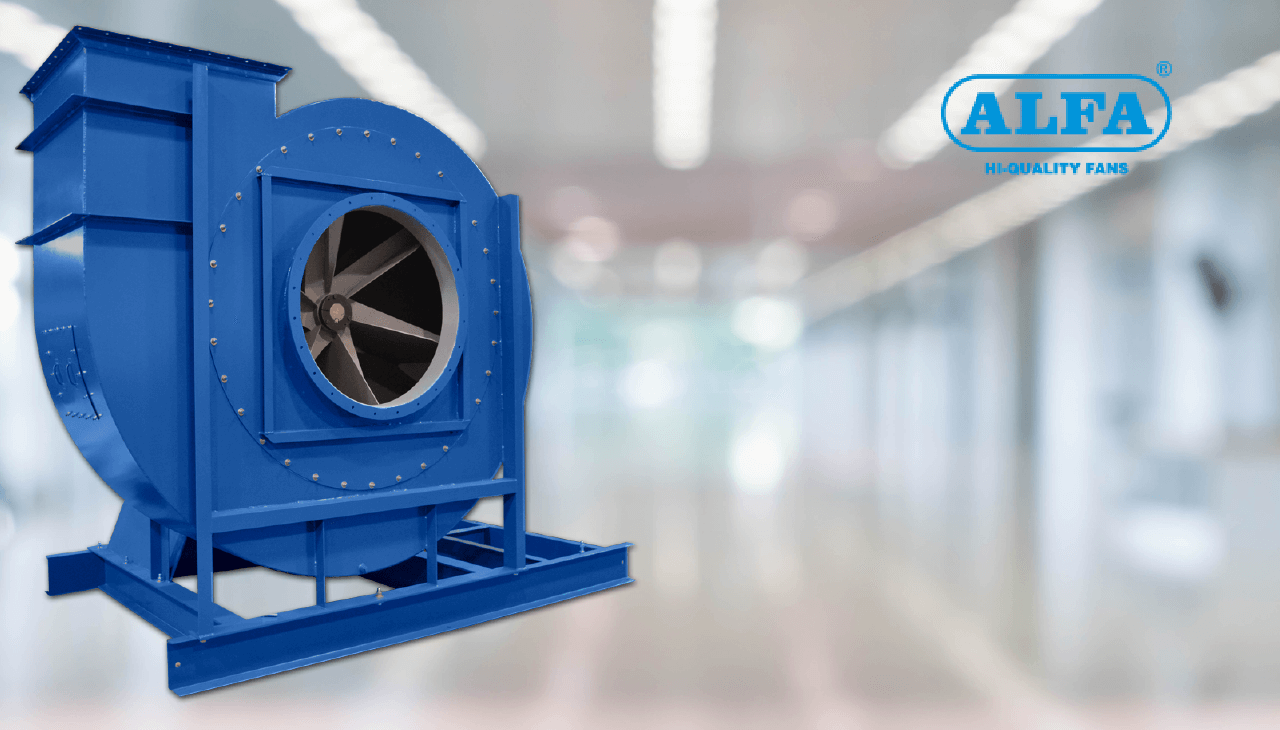

Many blowers fall under the classifications of Industrial Blowers, Industrial Cooling Fans, Industrial Exhaust Fan, Industrial Fan Blower, Industrial Fans and Industrial Ventilation Fans.

0 kommentar(er)

0 kommentar(er)